Sawing Machine Troubleshooting: Common Electrical Issues

Industry Background and Market Demand

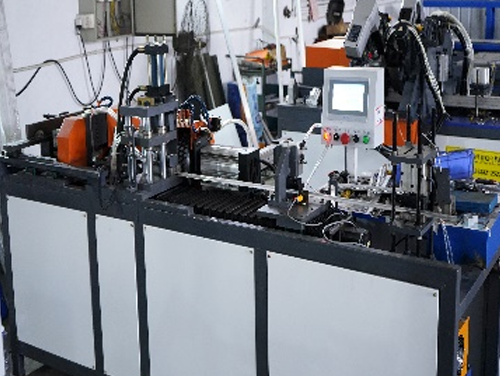

Sawing machines are essential in metalworking, woodworking, and construction industries, where precision and efficiency are critical. As industrial automation advances, electrical systems in sawing machines have become more sophisticated, integrating variable frequency drives (VFDs), programmable logic controllers (PLCs), and advanced safety mechanisms. However, electrical failures remain a leading cause of downtime, affecting productivity and maintenance costs.

The demand for reliable troubleshooting solutions has grown as manufacturers seek to minimize operational disruptions. Companies increasingly prioritize machines with modular electrical designs, allowing for easier diagnostics and repairs. Understanding common electrical issues—and their solutions—helps maintenance teams reduce unplanned downtime and extend equipment lifespan.

Core Electrical Components and Their Functions

Modern sawing machines rely on several key electrical systems:

1. Motor Control Circuits – Govern the saw blade’s speed and torque, often using VFDs for precision adjustments.

2. Safety Interlocks – Prevent operation when guards are open or sensors detect anomalies.

3. Power Supply Units – Convert and regulate voltage for control boards and peripherals.

4. Sensors and Feedback Systems – Monitor blade alignment, material feed, and overheating.

Failures in any of these systems can lead to erratic performance or complete shutdowns.

Common Electrical Issues and Troubleshooting Steps

1. Motor Fails to Start

Possible Causes:

- Blown fuses or tripped circuit breakers

- Faulty contactors or relays

- Damaged motor windings

Troubleshooting:

- Check power supply continuity with a multimeter.

- Inspect contactors for burnt contacts or loose connections.

- Test motor insulation resistance to detect winding failures.

2. Intermittent Operation

Possible Causes:

- Loose wiring or corroded terminals

- Overheating due to poor ventilation

- Failing capacitors in the motor circuit

Troubleshooting:

- Tighten all electrical connections and clean oxidation from terminals.

- Ensure cooling fans and vents are unobstructed.

- Measure capacitor capacitance with an LCR meter.

3. Erratic Speed Control (VFD-Related Issues)

Possible Causes:

- Incorrect parameter settings in the VFD

- Electromagnetic interference (EMI) disrupting signals

- Failing encoder feedback

Troubleshooting:

- Verify VFD programming matches motor specifications.

- Shield control cables and separate them from power lines.

- Test encoder output with an oscilloscope.

4. Frequent Circuit Breaker Tripping

Possible Causes:

- Short circuits in wiring or motor windings

- Overloaded circuits due to excessive load

- Ground faults from insulation breakdown

Troubleshooting:

- Perform insulation resistance tests on motor and cables.

- Verify machine load does not exceed rated capacity.

- Use a ground fault detector to locate leakage paths.

Key Factors Affecting Electrical Reliability

1. Component Quality – Low-grade contactors or wiring increases failure rates.

2. Environmental Conditions – Dust, moisture, and temperature fluctuations accelerate wear.

3. Maintenance Practices – Regular inspections prevent minor issues from escalating.

4. Proper Installation – Incorrect wiring or grounding introduces long-term risks.

Supplier Selection and Electrical Component Standards

When sourcing electrical parts for sawing machines, manufacturers should prioritize:

- Certifications – UL, CE, or IEC compliance ensures safety and durability.

- Supplier Reputation – Established brands (e.g., Siemens, ABB) offer better technical support.

- Modularity – Components with plug-and-play designs simplify replacements.

Industry Pain Points and Emerging Solutions

Common Challenges:

- Lack of standardized diagnostic tools across machine brands.

- Difficulty in training technicians on proprietary systems.

Innovations Addressing These Issues:

- Predictive Maintenance Sensors – IoT-enabled devices alert users before failures occur.

- Universal Diagnostic Interfaces – Some manufacturers now adopt open communication protocols (e.g., OPC UA).

Future Trends in Sawing Machine Electrical Systems

1. Increased Automation – AI-driven diagnostics will reduce manual troubleshooting.

2. Energy-Efficient Designs – Regenerative braking in motors cuts power consumption.

3. Enhanced Safety Integration – Smart sensors will detect electrical faults faster.

FAQ: Common Sawing Machine Electrical Problems

Q: Why does my sawing machine’s motor hum but not start?

A: This often indicates a faulty capacitor, single-phasing in three-phase systems, or a seized bearing.

Q: How can I reduce electrical interference in VFD-controlled saws?

A: Use shielded cables, install line reactors, and ensure proper grounding.

Q: What causes frequent overheating in the control panel?

A: Poor ventilation, undersized wiring, or excessive ambient temperatures are likely culprits.

By understanding these electrical issues and adopting proactive maintenance strategies, businesses can optimize sawing machine performance and reduce costly downtime.

यह वेबसाइट यह सुनिश्चित करने के लिए कुकीज़ का उपयोग करती है कि आपको हमारी वेबसाइट पर सर्वोत्तम अनुभव मिले।

टिप्पणी

(0)